Introduction

Toilet-room lavatory faucets in healthcare and food service facilities are not just plumbing fixtures; they are control points in both infection prevention and water and energy use. For architects and engineers working on clinics, hospitals, long-term care, commercial kitchens, and food processing environments, the decision to specify touchless faucets must be grounded in standards, hygiene evidence, and system-level performance rather than marketing claims.

This article summarizes key regulatory drivers (ADA, WaterSense, CALGreen, ASME), synthesizes hygiene-related research on sensor-operated faucets, and outlines specification strategies that prioritize durability, sustainability, and integration with building systems.

Hygiene Role of Touchless Faucets in High-Risk Occupancies

Health Facilities

Handwashing stations in patient rooms, staff areas, and public restrooms are part of a broader clinical water system that can both interrupt and propagate healthcare-associated infections. Studies on sensor-activated and electronic faucets in hospitals have reported:

- Colonization of some electronic faucet designs with opportunistic pathogens such as Pseudomonas aeruginosa and Legionella, particularly when internal mixing valves, complex flow paths, or elastomeric components provide niches for biofilm growth.

- Benefits of touchless operation in reducing surface contact on handles and escutcheons, recognized as high-touch points in multi-user restrooms.

From a design standpoint, the question is less “manual versus electronic” and more “which electronic designs are compatible with the facility’s infection-prevention and water safety strategy.” Internal geometry, materials, flushing strategy, and hot water system integration all affect risk.

Food Service and Food Handling Environments

In food service, toilet-room and back-of-house lavatory faucets support compliance with health code expectations for hands-free operation, reliable temperature control, and effective handwashing flow. Touchless faucets contribute by:

- Eliminate hand contact with handles following washing, thereby reducing the risk of recontamination just before staff return to food preparation or service.

- Forcing controlled run times and flow rates to ensure adequate rinsing without excessive consumption, which is important in high-throughput kitchens and restrooms.

These benefits are realized only if sensor detection zones, response times, and timeout parameters are tuned for glove use, quick hand movements, and peak traffic conditions typical of food service environments.

Regulatory and performance framework

Accessibility: ADA and Operable Parts

Accessible toilet rooms shall comply with the ADA Standards for Accessible Design, implemented by federal regulation. The text of the full section is as follows:

This implies the development of touchless toilet faucets, which include the following:

- Operable parts must be usable with one hand without tight grasping, pinching, or twisting of the wrist. Properly configured sensors inherently satisfy this requirement if the detection field is reliable.

- At least one compliant lavatory in each accessible toilet or bathing room must meet clear knee and toe clearance, height, and reach range requirements. Sensor lenses, displays, and any manual override control must remain within accessible reach ranges.

- Specifiers should verify that any optional manual control, mixing lever, or cleaning mode is also accessible, not just the infrared sensor.

Water Efficiency: WaterSense and CALGreen

WaterSense. The U.S. EPA WaterSense program sets performance-based efficiency criteria for bathroom sink faucets and accessories. Key references:

- Overview of WaterSense bathroom faucets

- WaterSense Product Specifications

- WaterSense bathroom faucet factsheet (PDF)

WaterSense-labeled lavatory faucets typically limit flow to a maximum of 1.5 gpm at 60 psi, at least 30% below the federal standard of 2.2 gpm, while maintaining performance. Many public-use sensor faucets operate at 0.5 gpm or lower, which is common for healthcare and food-service toilet rooms.

CALGreen. For projects in California, the CALGreen code (Title 24, Part 11) mandates and encourages reductions in indoor water use through prescriptive and performance pathways. Useful orientation resources include:

- CALGreen Indoor Water Use Overview

- Sample municipal guidance referencing CALGreen indoor water efficiency requirements

In practice, specifying WaterSense-labeled sensor faucets with 0.5 gpm (or lower, subject to user acceptance and code) makes it easier to document CALGreen and LEED-related indoor water reductions.

Product Standards: ASME A112.18.1

Touchless toilet-room lavatory faucets used in North America are expected to comply with ASME A112.18.1/CSA B125.1, the harmonized standard for plumbing supply fittings. Public access to the standard itself is controlled, but basic information can be found at:

This standard covers pressure, flow, endurance, and mechanical integrity tests. For AEC professionals, it provides a baseline expectation that touchless faucets will:

- Withstand cyclic operation-often hundreds of thousands of cycles-without leakage.

- Sustain performance over normal pressure variations.

- Use materials compatible with contact by potable water.

This is especially important for such industries as healthcare and food service, where access for maintenance might be limited and failures can interfere with operations.

Hygiene Performance and Microbial Risk Management

Reduction of Surface Contact and Fomite Control

From a surface hygiene perspective, touchless faucets remove the handle as a recontamination path after handwashing. Combined with touchless flush valves, dispensers, and door hardware, this can reduce the number of surfaces that require intensive disinfection cycles. Restroom hygiene studies have shown that high-touch components (including faucet handles) often carry elevated microbial loads and benefit from either contactless operation or more frequent cleaning.

This also aligns with the protocols of healthcare and food service by attempting to minimize fomite transmission in both public and staff sanitation.

Internal Water-Path Hygiene

Sensor-activated faucets introduce complexity inside the body: solenoid valves, mixing chambers, flow restrictors, and thermostatic elements. Research has documented that some electronic faucet designs can harbor higher burdens of opportunistic pathogens than manual faucets, particularly when:

- Water temperatures are within the range that supports organisms such as Legionella to grow.

- Dullness is extended because of dead legs or branches not utilized.

- Internal materials and geometries favor biofilm formation.

For project requirements, this implies the following technical recommendations:

- Use straight-through flow paths and minimize dead legs. Prefer faucet models with simplified internal passages that reduce stagnant volumes.

- Material selection. Where possible, avoid internal elastomers known to support biofilm; consider designs tested for performance in healthcare environments.

- Thermal regime and disinfection. Coordinate with the hot water system so that periodic thermal disinfection (for example, elevated temperature flushing) can be delivered to the faucet without damaging components.

- Automated flushing. Specify programmable or centrally managed flushing routines (for example, 60–120 seconds every 24 hours) to reduce stagnation in infrequently used toilet rooms.

The hygiene impact of touchless faucets is therefore strongly dependent on how the faucet design interacts with the facility water safety plan rather than the sensor technology alone.

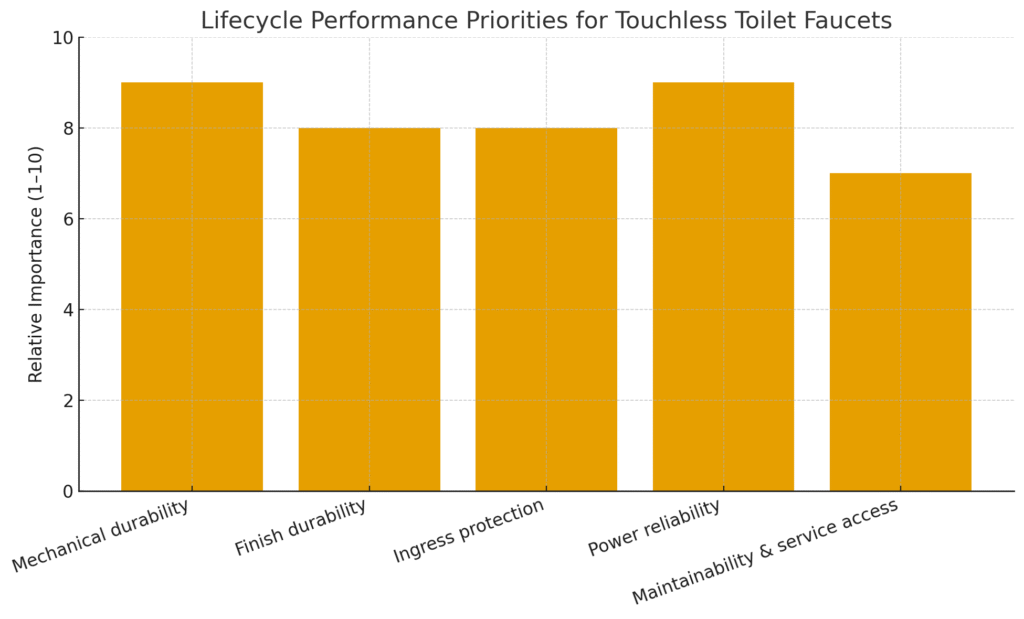

Durability and Life-Cycle Performance

Mechanical and Finish Durability

Healthcare and food service facilities experience high duty cycles, aggressive cleaning chemicals, and occasional impact loads from carts and equipment. When evaluating touchless faucets, A/E teams should consider:

- Body construction. Solid brass or stainless steel bodies with robust mounting hardware resist vandalism and repeated lateral loading more effectively than thin-wall castings.

- Finish durability. PVD or similar hard finishes better withstand disinfectants and degreasers commonly used in kitchens and clinical settings than basic electroplated coatings.

- Ingress protection. Electronics, sensors, and batteries should be housed to suitable ingress-protection levels to prevent failures from splashing, steam, or wash-down practices in back-of-house spaces.

ASME A112.18.1 endurance testing provides a baseline, but high-abuse environments may warrant additional project-specific criteria, such as vandal-resistance testing or documented field mean time between failures.

Power, Redundancy and Maintainability

Power strategy should be treated as a core design choice:

- Hardwired low-voltage power supplies are often preferred in healthcare, where predictable operation is essential and battery replacement can be logistically challenging.

- Battery-only configurations may be acceptable in smaller food-service projects but should include planned maintenance intervals and visible or remote indicators for low power.

- Hybrid or backup modes (for example, a manual override in case of sensor failure) can be valuable in critical locations such as surgical handwash stations or staff restrooms adjacent to operating suites.

Access for cartridge replacement, solenoid servicing, and sensor adjustment should be considered during layout, particularly when solid-surface or continuous countertops are used.

System Integration and Data

Integration of Building Management System (BMS)

Touchless toilet faucets can offer more than on/off control. If integrated with either BMS or a dedicated plumbing monitoring platform, they will be able to:

- Provide usage analytics in terms of number of activations, run time, and estimated consumption to inform water balance calculations and fixture right sizing.

- Allows central programming of flow rates, run times, and flushing intervals across a facility or campus.

- Generate alerts for abnormal use patterns that may indicate leaks, stuck valves, or sensor faults.

In large hospitals or food production complexes, this allows touchless faucets to participate in broader resource management and risk monitoring strategies.

Coordination with Water Safety and Environmental Controls

Sensor faucets should also be integrated with:

- Hot water recirculation design, to avoid dead legs and ensure required outlet temperatures for hygiene without scalding.

- Point-of-use filters, if specified by infection control for high-risk departments. These add pressure drop and must be compatible with the faucet’s flow control and sensor algorithms.

- Ventilation and humidity control, since restrooms with high moisture loads and poor exhaust can drive corrosion and electronics failures over time.

Guidance for Specification by A/E Teams

Healthcare Projects

For hospitals, clinics, and long-term care facilities, Division 22 specifications and plumbing schedules can include:

- Touchless lavatory faucets in patient, public, and staff toilet rooms complying with ASME A112.18.1/CSA B125.1 and WaterSense where applicable.

- Clear designation of locations requiring enhanced features such as programmable thermal disinfection support, integrated point-of-use filtration, or compatibility with the facility’s water safety protocols.

- Requirements for the manufacturer to document internal volume, recommended flushing regimes and compatibility with institutional infection control policies.

Food Service and Food Handling Facilities

For restaurants, central kitchens, and food processing facilities: Specify touchless faucets at toilet rooms and back-of-house handwash stations with flow rates that meet health code guidance while aligning with WaterSense and CALGreen objectives where applicable. Emphasize chemical- and impact-resistant bodies and finishes, and ensure ingress protection is suitable for wash-down cleaning regimes. Coordinate faucet controls with operational practices (for example, staff wearing gloves and high peak flows during shift changes) to avoid nuisance shutoff or non-activation.

Conclusion

Touchless toilet-room lavatory faucets can provide meaningful hygiene and sustainability benefits in healthcare and food service facilities when they are treated as engineered components embedded in a regulated water and building-systems context. By grounding specifications in ADA accessibility requirements, EPA WaterSense and CALGreen water-efficiency criteria, and ASME A112.18.1 performance standards—and by explicitly addressing microbial risk, durability, and system integration—architects and engineers can move beyond product claims and design faucet systems that support long-term infection control, resource conservation, and reliable operation in demanding commercial and institutional environments.

| Lifecycle Priority | What It Involves | Key Specification Notes |

|---|---|---|

| Mechanical durability | Solid brass or stainless-steel bodies, robust mounting hardware, resistance to vandalism and repeated lateral loading. | Prefer solid brass/stainless bodies; specify robust mounting for high-abuse environments (healthcare, food service, carts, heavy use). |

| Finish durability | Resistance of faucet finishes to aggressive disinfectants and degreasers. | Favor PVD or similar hard finishes over basic electroplated coatings, especially in clinical and kitchen environments. |

| Ingress protection for electronics | Protection of sensors, batteries, and electronics from splashing, steam, and wash-down. | Require suitable ingress protection ratings for back-of-house and high-moisture areas; coordinate with cleaning methods (e.g., spray-down regimes). |

| Power reliability & redundancy | Choice of hardwired, battery, or hybrid power; backup/manual modes for critical locations. | In healthcare, prioritize hardwired low-voltage power; in smaller food-service, battery may be acceptable with clear maintenance cycles and low-power alerts. |

| Maintainability & service access | Ease of cartridge replacement, solenoid servicing, and sensor adjustment. | Ensure access in layouts with solid-surface or continuous countertops; specify requirements for service clearances and tool-free or simplified maintenance. |

| Overall endurance & life-cycle performance | Ability to withstand high duty cycles, pressure variations, and long-term use without leaks or failures. | Require compliance with ASME A112.18.1 endurance testing; consider additional vandal-resistance or MTBF documentation for high-abuse or mission-critical areas. |

No responses yet