Commercial sensor-operated faucets and flush valves are now standard in airports, hospitals, higher education, and other institutional restrooms. Yet in many projects, power architecture and battery life receive less attention than hydraulics or hardware durability. For high-use facilities, the choice between battery packs, low-voltage hardwire, or hybrid power architectures can have significant effects on lifecycle cost, maintenance, and sustainability.

This article evaluates power options, duty-cycle behavior, and relevant frameworks including ADA, WaterSense, CALGreen, and ASME A112.18.1/CSA B125.1. It is written for architects, engineers, and specifiers developing high-reliability commercial and institutional restroom systems.

Regulatory and Standards Context

ADA requirements and control accessibility

The Americans with Disabilities Act (ADA) provides mandatory accessibility requirements for lavatories and operable parts. Key references include:

ADA Standards for Accessible Design:

ADA Standards for Accessible Design

U.S. Access Board Technical Guide for Lavatories and Sinks (Chapter 6):

U.S. Access Board Technical Guide for Lavatories and Sinks (Chapter 6)

Design implications for powered faucets:

- Sensor windows and manual override buttons must fall within ADA reach ranges, typically 48 inches for forward reach or 44 inches when reaching over obstructions.

- Knee and toe clearance under lavatories must not be reduced by battery packs, power supplies, or conduit routing.

- Operable parts must allow one-handed operation without tight grasping, pinching, or twisting of the wrist; this affects placement of battery modules or service compartments.

- Clearance and maintainability must be coordinated early with casework, plumbing rough-in, and electrical layouts.

WaterSense Performance and Flow-Rate Constraints

The U.S. Environmental Protection Agency’s WaterSense program provides performance and efficiency criteria for water-using fixtures:

WaterSense Program Overview:

WaterSense Bathroom Faucets:

WaterSense Product Specifications:

WaterSense Product Specifications

WaterSense includes minimum performance thresholds and requires at least 20% water savings relative to federal baselines. While lower flow rates reduce water volume per activation, electrical consumption during each activation is driven more by solenoid duty time than by flow.

For specifiers:

- Reduced run times (e.g., from 12 seconds to 8 seconds) meaningfully reduce water consumption, but only modestly reduce battery load.

- WaterSense-listed faucets can lower building-level hot water energy use, even if battery consumption remains relatively constant.

CALGreen Requirements for High-Efficiency Flow

California’s Green Building Standards Code (CALGreen) establishes mandatory water efficiency requirements, including:

Nonresidential lavatory faucets no more than 0.5 gpm at 60 psi Section 5.303.3.4.1

Summary reference:

Implications:

- 0.5 gpm paired with programmed run times (often 8–12 seconds) results in very small per-use volumes (~0.07–0.1 gallons).

- High-traffic facilities may experience many short activations per day, increasing the importance of realistic battery-life modeling.

- CALGreen projects often require coordination between water-efficiency targets, sensor placement, and power architecture.

ASME A112.18.1/CSA B125.1 Standard for Plumbing Supply Fittings

This joint U.S.–Canadian performance standard governs durability, hydraulic characteristics, and safety for supply fittings:

ASME A112.18.1/CSA B125.1 standard information:

ASME A112.18.1/CSA B125.1 standard information

For powered faucets, the standard covers solenoid cycle durability and components exposed to water. While it does not dictate battery configuration, its cycle durability benchmarks influence power consumption over a fixture’s lifespan.

Specifications should require compliance with ASME A112.18.1/CSA B125.1 for all sensor faucets, metering systems, and solenoid-actuated fittings.

Power Architectures in Commercial Toilet Faucets

Self-sufficient battery-powered faucets

Common configurations include 4–6 AA alkaline cells or lithium-based equivalents.

Advantages:

- No conduit or transformer installation.

- Simple compatibility retrofit.

Constraints:

- Relies on manual maintenance programs for battery replacement.

- The environmental impact of constant alkaline cell replacement.

- Batteries must be mounted outside ADA knee space and protected from cleaning chemicals.

Low-voltage hardwired systems

Used in many new or major renovation projects.

Characteristics:

- Uninterrupted power availability.

- Supports advanced control features: telemetry, data reporting.

- Requires early coordination with electrical design and casework.

Limitations:

- Dependent upon building power unless a backup strategy is provided.

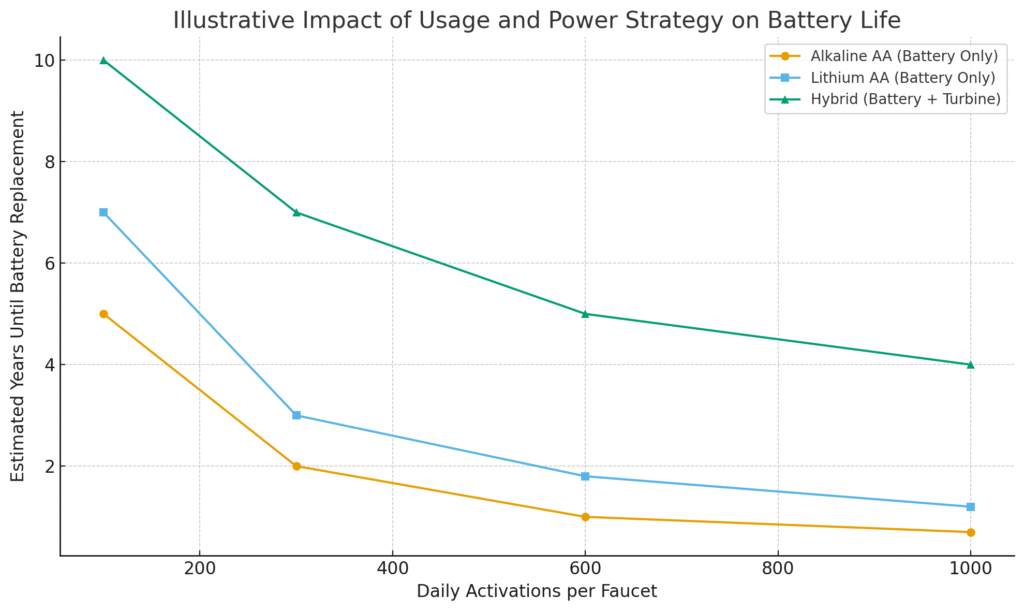

Hybrid battery + energy-scavenging systems

These systems combine a battery pack with a turbine-driven generator.

Benefits:

- Can extend battery change intervals to multiple years in high-use facilities.

- Reduced waste and maintenance.

Considerations:

- Turbine provides a minor pressure drop.

- Strainers need periodic cleaning.

- Best suited to facilities with consistent, high activation volumes.

Electrical Load Profiles and Duty Cycles

Power stages of a sensor faucet

A typical activation includes:

- Standby mode: current consumption is extremely low for IR or capacitive sensors.

- Active/detection mode: medium power consumption by the control electronics.

- Solenoid actuation: short, high current pulses to open/close valve.

Battery life is affected mostly by activation count rather than time in service.

Estimating Battery Life

Typical activation profiles:

- Light use: 50–100 activations/day

- Medium use: 150–300 activations/day

- Heavy use: 500–1,500 activations/day

Specifiers should request manufacturer test documentation showing:

- Chemistry and battery capacity

- Testing pressure and flow conditions

- Number of Activations until batteries reach 80% of rated voltage

Specifications should express minimum performance in cycles, not years.

Battery Chemistry, Durability, and Environmental Concerns

Alkaline vs. lithium chemistries

Alkaline AA:

- Inexpensive and easily accessible

- Smaller life with high-drain use

- More frequent maintenance cycles

Lithium AA:

- Better high-drain performance

- Wider temperature range

- Higher recycling and end-of-life considerations

Based on usage density and sustainability goals, select appropriate battery chemistry.

Ingress protection and enclosure design

Battery compartments shall provide:

- Appropriate moisture resistance (e.g., IPX4 or higher depending on location)

- Chemical resistance to cleaning agents

- Serviceability without removing faucet body, or interfering with ADA clearances

Sustainability and System-Level Efficiency

Interaction water + energy

While electrical consumption per cycle is modest, water savings have larger system-level impacts:

- Reduced potable water use

- Reduce hot water generation and distribution energy

- Reduced wastewater treatment loads

Improvements in sensor logic (e.g., tighter detection windows, adaptive run times) further reduce waste.

CALGreen and regional water demands

CALGreen-driven efficiency targets reduce building-level energy use associated with water heating and pumping. Facilities with high daily activation counts should assess battery strategies against long-term environmental goals.

System Integration and Telemetry

Centralized power and monitoring

Hardwired systems can be integrated into building management systems (BMS) using BACnet, Modbus, or vendor APIs.

Advantages include:

- Usage tracking

- Fault monitoring

- Condition-based maintenance scheduling

Wireless modules and Power impact

When wireless telemetry is powered by a battery:

- Transmission intervals impact battery life.

- Specifications should define acceptable reporting frequencies and latency

- Event-based reporting e.g., faults only can save battery capacity

Specification Guide for Architects and Engineers

Performance requirements

Specifications should require:

- Compliant to ASME A112.18.1/CSA B125.1

- Flow rates at or below WaterSense (where applicable) and CALGreen 0.5 gpm limits

- Standard run times and anti-vandal lockout periods

- Documented battery life only in cycles, not in years.

Power Architecture requirements

For battery or hybrid systems:

- Specify minimum acceptable number of activations before replacement

- Shall include accessible battery compartments that do not interfere with ADA clearances

For hardwired systems:

- Define the voltage, transformer type, and any gateways required for BMS integration.

ADA coordination

Include:

ADA Standards for Accessible Design:

ADA Standards for Accessible Design

U.S. Access Board Lavatories Guide:

U.S. Access Board Lavatories Guide

Require coordination of sensor windows, battery locations, and power supplies to maintain reach, knee, and toe clearances.

Submittals

Need:

- WaterSense listings where applicable

- ASME A112.18.1/CSA B125.1 Compliance Documentation

- Battery life test reports

- Power distribution diagrams (for hardwired systems)

Commissioning and Operations

End Functional testing

Commissioning should verify:

- Sensor detection range in field lighting

- Run-time settings

- Solenoid function on low and high pressures

- Power loss response for hardwired systems

maintenance practices

Adopt:

- Usage-based battery replacement

- Regular strainer inspection in hybrid turbine models

- Checks for dampness underneath sink electronics

- Standardization of battery chemistries to reduce maintenance errors

Conclusion

Power architecture—battery, hardwired, or hybrid—is not a secondary consideration in commercial restroom design. It directly influences durability, maintainability, ADA coordination, sustainability performance, and user reliability. By linking power strategy with WaterSense flow control, CALGreen efficiency criteria, and ASME durability standards, design teams can produce clearer, longer-lasting Division 22 specifications that remain aligned with actual facility operating conditions. This engineering-driven approach ensures that commercial toilet faucets function reliably, minimize energy and water use, integrate with building systems, and maintain accessibility over the lifespan of the installation.

| Daily Activations per Faucet | Alkaline AA (Battery Only) – Years | Lithium AA (Battery Only) – Years | Hybrid (Battery + Turbine) – Years |

|---|---|---|---|

| 100 | 5.0 | 7.0 | 10.0 |

| 300 | 2.0 | 3.0 | 7.0 |

| 600 | 1.0 | 1.8 | 5.0 |

| 1000 | 0.7 | 1.2 | 4.0 |

No responses yet