Commercial Toilet Faucets Play a Building Sustainability Role

Toilet faucets service both restrooms and public washrooms in commercial and institutional buildings and can play an important part in the overall sustainability profile of a facility. These fixtures directly impact a building’s potable water consumption, hot water energy demand, accessibility compliance, and long-term maintenance performance.

Architects, engineers and specifiers need to select faucets based on performance data, lifecycle robustness, standard adherence and the ability to integrate with more holistic watermanagement programs. The impact of a faucet is magnified when applied in high-traffic buildings such as: airports, universities, stadiums, healthcare facilities and transit hubs.

Regulatory and Voluntary Framework

ADA Accessibility Requirements

Scoping and technical requirements for the 2010 ADA Standards for Accessible Design cover items such as, but not limited to, lavatories and faucet operability. The major ADA provisions that address faucets specifically include the following:

- Lever, paddle, push or sensor controls operable with one hand

- Do not cling too tightly and do not nip or twist the wrist.

- Controls requiring low operating forces

- Proper reach range and clear floor space

- Knee and toe clearance and protection of supply piping

Technical References:

- ADA 2010 Standards:

ADA 2010 Standards - U.S. Access Board guide for lavatories and sinks:

U.S. Access Board Lavatories and Sinks Guide

WaterSense Criteria for Lavatory Faucets

The U.S. EPA WaterSense specification limits bathroom faucet flow to 1.5 gpm at 60 psi. Most commercial sensor faucets operate between 0.5 to 1.0 gpm, depending on the selection of aerator and pressure conditions. Certification to WaterSense requires independent testing for both performance and efficiency.

Resources:

- WaterSense bathroom faucets:

WaterSense Bathroom Faucets - WaterSense Bathroom Faucet Factsheet (PDF):

WaterSense Bathroom Faucet Factsheet

CALGreen Requirements for Nonresidential Faucets

California Green Building Standards Code – CALGreen, Title 24 Part 11 – establish performance limits for nonresidential lavatory faucets and require documented potable water use reductions when using either the Tier 1 or Tier 2 compliance path.

Typical CALGreen requirements include the following:

- 0.5 gpm maximum for nonresidential lavatory faucets at 60 psi

- Tier 1: roughly 12% water savings under baseline

- Tier 2: around a 20 percent cut

Resources:

- Overview of CALGreen plumbing fixtures:

CALGreen Plumbing Fixture Requirements - DSA CALGreen guidelines:

DSA CALGreen Guidelines - California Green Building Code plumbing fixtures summary:

California Green Building Code Plumbing Fixtures Summary

Compliant to ASME A112.18.1 / CSA B125.1

ASME A112.18.1/CSA B125.1 covers the requirements for plumbing supply fittings performance. Products include:

- Pressure and Leakage Test

- Durability and cycle testing

- Flow performance validation

- Corrosion and material safety

- Mechanical Integrity: Thermal and Hydraulic Conditions

References:

- Summary of ASME/CSA fitting standard:

ASME A112.18.1 / CSA B125.1 Summary - Overview of ANSI about ASME A112.18.1-2018:

ANSI/ASME A112.18.1-2018/CSA B125.1-18 Plumbing Fittings

Engineering Characteristics That Drive Eco-Impact

Flow rate and hydraulic control

The flow rate and run time, therefore, are the major driving factors behind the profile of water usage. Critical factors include:

- Pressure compensating aerators to stabilize flow at variant system pressures

- Minimum operating pressure required for proper mixing and flow

- Coordinating with domestic water distribution zones: helping to avoid the pressure drops that disrupt the performance of sensors.

Control modes: manual, metering, sensor

- Manual faucets rely entirely on user behavior and, as a rule, are turned on for a longer period of time.

- Metering faucets deliver a specified amount per cycle. CALGreen, and similar codes, typically specify 0.20 gallons per cycle as maximum for metering applications.

- Sensor faucets cut unnecessary flow by means of automatic start/stop logic and programmable time-outs. They also offer touch-free operation, supporting hygiene.

Durability and Lifecycle Engineering

ASME A112.18.1/CSA B125.1 Faucet Durability Although this Standard cannot address the long-term performance of faucets, experience has shown that long-term performance is related to design:

- Long-life Cartridges, Solenoids and Seals

- Corrosion-resistant finishes compatible with commercial cleaning products

- vandal resistant aerators and supplies with concealed mounting for public restrooms

A long-lasting faucet reduces the number of maintenance calls, minimizes leakage, and has a lower lifecycle environmental impact.

Integration with Building Systems

Domestic Water & Pressure Zoning

Proper performance depends on the coordinated design of the water system.

- PRVs may be needed to stabilize faucet performance.

- Fixture unit calculations give the proper sizing of the pipes.

- Hot water recirculation loops must be balanced to conserve pre-run waste.

Building Management Systems and Telemetry

More elaborate facilities may include faucets with:

- Submetering locally

- Occupancy and usage analytics

- Leak-detection alerts

- Automated monitoring of abnormal run times

These systems allow operators to quantify water savings and rapidly identify maintenance issues.

Hygiene and Public Health

Design decisions that reduce splash, improve ergonomics, and minimize contact points can enable hygiene and sustainability by saving labor in cleaning and consumption of water and chemicals.

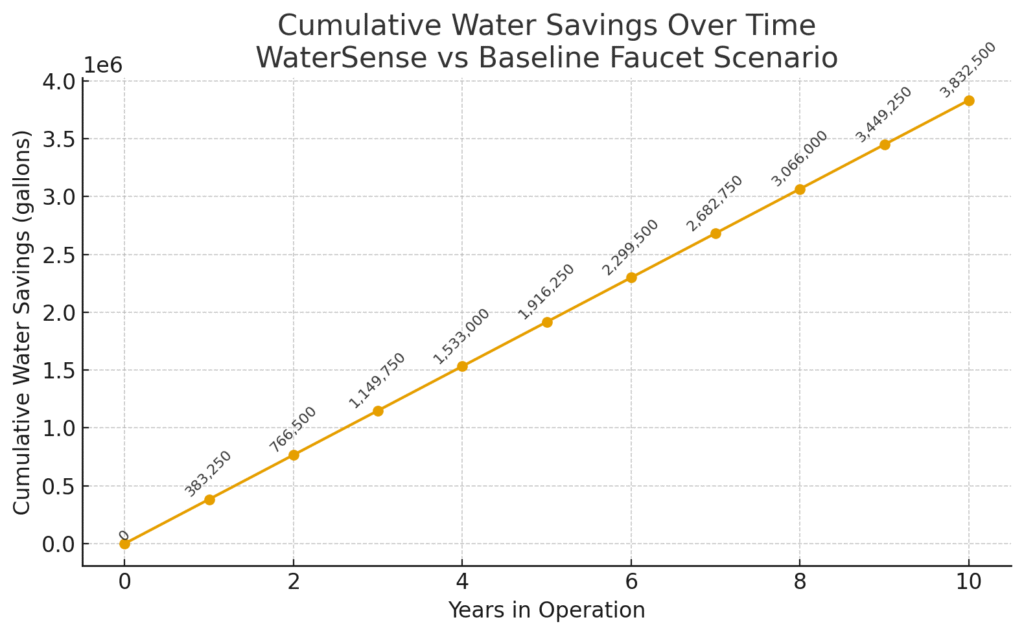

Eco-Impact Calculation Example

Assumptions:

30 faucets

200 uses/day each

Average execution time: 15 seconds

365 days/year

Base Case 2.2 gpm

0.55 gallons per use

3,300 gallons/day

1,204,500 gallons/year

WaterSense-Level Case (1.5 gpm)

0.375 gallons per use

2,250 gallons/day

821,250 gallons/year

Annual Savings

Approximately 383,250 gallons per year

Hot water energy savings also serve to further reduce environmental impact, especially when 30–40 percent of lavatory water is heated. For CALGreen projects, these calculations are useful in helping illustrate prescriptive water use reductions.

Specification Guidance for AEC Teams

Performance Specifications for Division 22

- Maximum flow rate: ≤ 1.5 gpm (WaterSense) or ≤ 0.5 gpm (CALGreen)

- Conform to ASME A112.18.1/ CSA B125.1

- Variable sensor or metering control parameters

- Easily accessible control designs meeting ADA reach and operability requirements

- Anti-corrosion finishes and lead-free material

- Replaceable cartridges and aerators with documented cycle life

Architectural Coordination

- Ensure that basin geometry prevents splashing at low flow rates

- Provide ADA-compliant clearances

- Provide vandal-resistant features in high-risk environments.

Commissioning and Post-Occupancy

- Check field flow rates

- Validate sensor time-outs and default programming.

- Track actual usage data post-occupancy

- Adjust accordingly in order to keep the set water performance targets.

Relationship to Broader Sustainability Frameworks

Commercial toilet faucets:

Indoor Water Use Reduction Strategies

LEED

Owner ESG water conservation goals

Public health compliance and reliability within essential facilities.

Specifying faucets that support WaterSense, CALGreen, ADA, and ASME improves long-term building performance and operational sustainability.

Conclusion

With appropriate engineering selection criteria in place, commercial toilet faucets are a proven tool to curb water use, enhance hygiene, and contribute to overarching whole-building sustainability goals. Specification of commercial toilet faucets through online platforms such as CommercialToiletFaucets.com has grown in popularity among AEC professionals. can enhance building performance in the following areas:

- Verified low-flow performance

- Projects must meet the requirements of WaterSense, CALGreen, ADA and ASME

- Smart integration with building water systems and monitoring tools

Systems-focused approaches to faucet selection deliver quantifiable water savings that continue to drive environmental stewardship for both commercial and institutional facilities.

| Framework / Standard | Scope / Application | Key Faucet-Related Requirements | Useful References |

|---|---|---|---|

| ADA 2010 Standards | Accessibility of lavatories and faucet operability in public/commercial facilities | One-hand operable controls (lever, paddle, push, sensor), no tight grasping or twisting of the wrist, low operating forces, proper reach range and clear floor space, knee and toe clearance, protected supply piping | ADA 2010 Standards · U.S. Access Board Lavatories & Sinks Guide |

| WaterSense (U.S. EPA) | Efficiency and performance of bathroom/lavatory faucets | Max 1.5 gpm at 60 psi; most commercial sensor faucets operate ~0.5–1.0 gpm; independent testing required for both performance and efficiency to earn label | WaterSense Bathroom Faucets · WaterSense Faucet Factsheet (PDF) |

| CALGreen (Title 24 Part 11) | California Green Building Standards for nonresidential buildings | 0.5 gpm max for nonresidential lavatory faucets at 60 psi; Tier 1 ~12% water savings; Tier 2 ~20% water savings vs baseline; requires documented potable water use reductions | CALGreen Plumbing Fixture Requirements · DSA CALGreen Guidelines · CALGreen Faucets & Fountains Summary |

| ASME A112.18.1 / CSA B125.1 | Plumbing supply fittings performance and safety | Pressure and leakage tests, durability and cycle testing, flow performance validation, corrosion/material safety, mechanical integrity under thermal and hydraulic conditions | ASME A112.18.1 / CSA B125.1 Summary · ANSI/ASME A112.18.1-2018/CSA B125.1-18 Plumbing Fittings |

No responses yet