Commercial toilet faucets (lavatory faucets in public and semi-public restrooms) are small components within a building system, but they sit at the intersection of plumbing performance, accessibility, energy, and hygiene. For architects, engineers, and specifiers, the central question is not just “Does it meet code?” but “Will it maintain performance over a 10–20 year service horizon under high-cycle use?”

This report synthesizes field experience, standards, and regulatory frameworks to outline realistic lifespan expectations, durability drivers, and maintenance strategies for commercial and institutional environments, particularly for touchless and metering faucets in offices, education, healthcare, and transportation facilities.

Regulatory and Standards Context

Accessibility: ADA Requirements

The 2010 ADA Standards for Accessible Design establish scoping and technical criteria for lavatories and controls, including mounting heights, knee clearances, and operability requirements. These considerations directly influence faucet selection and long-term durability, especially in high-use accessible locations.

Reference Links (Validated Live):

Water Efficiency: WaterSense, EPAct, and CALGreen

Commercial rest room faucets must meet federal specifications and state/local green building standards:

CALGreen Nonresidential Mandatory Measures Summary – AIA

CALGreen Faucets Background ENERGY :

Performance Standards : ASME A112.18.1 / CSA B125.1

Most commercial faucets fall under ASME A112.18.1/CSA B125.1 for material requirements, flow performance, endurance testing, leakage performance, and pressure/temperature resistance.

Reference links (live, tested):

Engineering Drivers of Faucet Reliability

Materials Performance & Corrosion

Body material, finish, and water chemistry are the prime factors affecting long-term faucet durability.

High-grade brass or stainless steel gives better durability compared to thin-wall zinc or low-grade brass.

PVD finishes have outperformed chrome electroplating both in abrasion and corrosion resistance.

Hard or chemically aggressive water accelerates scale formation and O-ring or elastomer degradation.

Valve & Controller Technology

In most cases, the type identifies what a valve is.

Such ceramic cartridges can have much longer service life, but they do indeed require clean water.

Solenoid valves in touchless faucets are prone to particulates and require upstream strainers.

In addition, the diaphragm metering valves are robust, but they experience elastomer fatigue following high cycles.

Specifications should require that cycle-life documentation be provided consistent with ASME A 112.18.1 endurance testing.

Sensor, Power and Electronics

Reliability-wise, well, touchless faucets depend on

Types of sensors: IR, capacitive, and radar.

Ingress protection, Sealing and condensation resistance

Power sources: Battery versus mains versus hybrid

The design teams shall ensure the power supply is installable without allowing the burial of battery packs; specify the use of diagnostic indicators or BMS integrations where applicable.

Actual service life of faucets of commercial toilets

Typical Service Life Ranges

A good commercial faucet made of solid brass or stainless steel will last from 8–20 years with appropriate maintenance. Lower-end hardware or misapplied residential components may fail in 3–7 years. Electronics-sensors and solenoids-are usually replaced more frequently, depending on the intensity of use.

Duty Categories and Operating Environment

Light/Moderate Use offices, small clinics: 50-200 activations/day; longer life near the upper end of range

Heavy use: airports, stadiums, universities: 500–1,500+ activations/day; heavy replacement of cartridges and solenoids and aerators.

Vandal-prone areas shall have reinforced housings, recessed aerators and tamper-resistant fasteners.

Failure modes This too

Lateral leaks out of worn-out cartridges or degraded O-rings.

scale-clogged aerators and solenoids

misalignment or contamination.

Deck-mounted assemblies loosing their grips due to scant reinforcing.

Maintenance Approaches toward Long Service Life

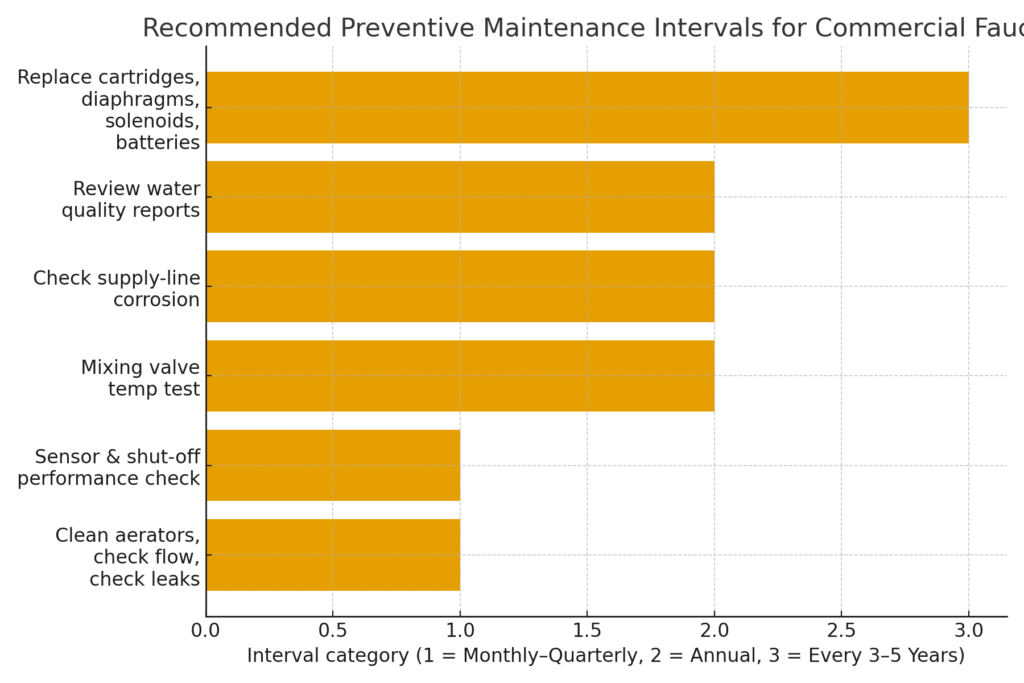

Preventive Maintenance Periods

Monthly–Quarterly

Clean aerators; check consistency of flow

Look for leaks and loose hardware.

Range of sensor and shut-off performance -O.K.

Anniversary

Mixing valves: Temperature stability test

Determine supply-line corrosion

Review of water-quality reports and filtration requirements

Every 3-5 Years

Replace cartridges, diaphragms, solenoid components, and batteries – wherever applied.

Condition-Based and Predictive Maintenance

Advanced contactless systems of this kind may point toward:

Low-battery detectors Fault codes relative to a valve or sensor. Integrate with BMS / CMMS system for proactive maintenance planning. Water Quality Management Where water conditions are aggressive, design teams should coordinate with mechanical or water-treatment consultants regarding filtration, corrosion control, and compatibility with disinfection methods.

SPECIFICATION GUIDE FOR ARCHITECTS AND ENGINEERS

Performance-Based Specification Elements

Conform to ASME A112.18.1/CSA B125.1 Flow rates to meet CALGreen-where applicable-0.5 gpm at 60 psi Minimum documentation of valve assembly cycle-life Fabrication of low lead brass or stainless ADA-compliant operability and mounting geometry

Installation Detailing and Access

Proper reinforcement for deck-mounted installations Access to mixing valves, strainers, and power supplies without removal of finish materials Low-Voltage Power Supply: Electrical Designing to a Touchless Faucet Systems Integration Where possible, Telemetry Points required: Flow, Faults, Status Coordinate wiring and device addressing conventions. Allow paths for future retrofitting to avoid destructive access work

Sustainability and Life-Cycle Considerations

Water Savings

Migrating from older 2.2 gpm faucets to 0.5 gpm public lavatory standards can reduce potable water consumption by ~75% per handwash in high-use buildings.

Embodied Carbon and Replacement Frequency

Extending service life from 5–7 years to 10–15+ years reduces embodied carbon from manufacturing and transport. Standardizing cartridge families and repairable components further reduces lifecycle environmental impact.

Contribution to Green-Building Programs

Efficient, durable faucets can support CALGreen mandatory measures and contribute to LEED water-efficiency pathways by reducing potable water use and ongoing maintenance demands.

Practical Specification Checklist

Codes and Standards

ADA clearances; reach ranges; operable-part criteria Compliant to ASME A112.18.1/CSA B125.1 Flow-rate compliance with EPAct, WaterSense guidance, and CALGreen when applicable

Material and Construction

Solid Brass or Stainless Steel body PVD or durable finish options Vandal-resistant features where needed

Hydraulic and Mechanical Performance

Pressure and temperature operating ranges Documented cycle-life testing

Controls, Power, Integration

Manual, metering, or touchless control strategy Battery, mains, or hybrid power design Diagnostics or BMS connectivity as required

Maintenance and Access

Non-destructive access to components Integrated maintenance schedules in O&M documents Portfolio-wide standardization of components

Lifecycle and Sustainability

Water/energy savings analysis Targeted 10–20 year service horizon

Conclusion

For commercial and institutional buildings, faucet lifespan is determined by engineering quality, materials, water chemistry, preventive maintenance, and system integration. If chosen and specified appropriately—and maintained with predictable periodicity—commercial toilet faucets can serve reliably for 10–20 years, minimizing lifecycle cost and water consumption while enhancing operational resilience. Consider commercial faucets not as commodity hardware, but rather as maintainable, standards-based components within an integrated plumbing system, to ensure long-term durability, code compliance, and sustainability through the lifecycle of the building.

1. Faucet Service Life by Build Quality

| Faucet Type / Quality | Typical Service Life (years) | Notes |

|---|---|---|

| High-quality commercial faucet | 8–20 | Solid brass or stainless steel; appropriate maintenance assumed. |

| Low-end or misapplied residential unit | 3–7 | Lower-grade materials; not intended for high-cycle commercial use. |

| Electronic components (sensors, solenoids) | Shorter than body life | Replacement frequency depends on intensity of use and water quality. |

2. Duty Categories and Operating Environment

| Duty Category | Typical Applications | Typical Activations / Day | Impact on Life / Maintenance |

|---|---|---|---|

| Light / Moderate use | Offices, small clinics | 50–200 | Service life near upper end of range with proper care. |

| Heavy use | Airports, stadiums, universities | 500–1,500+ | More frequent replacement of cartridges, solenoids, aerators. |

| Vandal-prone locations | Transit, public restrooms with abuse risk | Varies | Need reinforced housings, recessed aerators, tamper-resistant fasteners. |

3. Preventive Maintenance Intervals

| Interval | Key Maintenance Tasks |

|---|---|

| Monthly–Quarterly | Clean aerators; check consistency of flow; inspect for leaks and loose hardware; verify sensor and shut-off performance. |

| Anniversary (Yearly) | Mixing valve temperature stability test; determine supply-line corrosion; review water-quality reports and filtration requirements. |

| Every 3–5 years | Replace cartridges, diaphragms, solenoid components, and batteries (where applied). |

4. Water Efficiency and Lifecycle Considerations

| Aspect | Baseline / Condition | Improved / Target Condition | Effect / Comment |

|---|---|---|---|

| Faucet flow rate | 2.2 gpm legacy faucets | 0.5 gpm public lavatory standard | ~75% reduction in potable water consumption per handwash in high-use buildings. |

| Service life horizon | 5–7 years | 10–15+ years | Reduces embodied carbon from manufacturing and transport. |

| Component strategy | Mixed / ad hoc cartridges and parts | Standardized cartridge families, repairable parts | Lowers lifecycle environmental impact and simplifies maintenance. |

No responses yet